Ivan Sutherland invented the first CAD software in 1963 with “Sketchpad.” By the early 90’s computer generated drawings moved from 2D to 3D. They’ve been an important part of the design process for nearly 30 years, first supplementing physical modeling, and now almost entirely replacing it (unfortunately, there’s some things that a computer just can’t do!). The proliferation of BIM software like Revit and parametric tools like Rhino’s Grasshopper have made the amount of information that a 3D model can hold previously unthinkable, while advancements in computer hardware and software like OpenGL have made distributing that information seamless.

Despite being used for 30 years and reaching a point of near zero friction, the way that models are used is still primarily internal. Much of this is rooted in the legal framework of the construction process. Drawings are what building and zoning departments use to approve or deny projects. They are the main source of information for every stakeholder in a project, and need to convey all the information required to accurately and safely construct something. They also serve as legal and binding contracts between the client, contractor, architect, engineer, subs and government. If it’s not built properly, someone either omitted important information, or didn’t read the plans properly…that’s no bueno. They are extremely time consuming to produce and can hold a lot of liability for whoever is producing them. Unlike 3D models, plans on paper don’t require a computer or knowledge of often complex software to review them. For these reasons, printed 2D drawings are the primary documents that are created and distributed on every project. However, they have limitations and often fall short of accurately conveying design and construction intent from the designer to the rest of the teams.

Often, 3D models and renderings are an additional cost that a client can choose to add into their agreement with the designer. Renderings may cost hundreds of dollars per image, and possibly thousands if it is to be photo-realistic and materially accurate. They take lots of time and computing to generate accurately, even with today’s tools1.

In our process and at many design studios with the technical skillset to do so, it’s how we start a project. We work in 3D software to design, and then we translate those models into a complete set of construction documents. It’s an iterative process where each informs the other and they get refined together throughout the process. Usually, the client is being billed for these hours whether or not they purchase the opportunity to see them or not. Typically what happens is after the construction documents are done, the designer goes back and creates renderings for their portfolio. This is dumb, for multiple reasons.

That is why we’ve decided that when you work with us, you always get a 3D model walkthrough and renderings.

We think it’s time to move forward with how the design process works. AEC (architecture, engineering and construction) is one of the slowest industries to adopt innovation, and this is a prime example. We’ve had the ability to do this for 30 years, yet few are willing to switch up how things are done! In the past when our clients have requested renderings or a model to view, it’s been extremely beneficial for both us and them. Here’s just a few of the benefits we see from providing imagery:

It reduces confusion for our clients. If you don’t have a background in reading drawings, you’re probably not going to be able to take a plan and fully visualize the space. It’s a learned skill, and one that comes more easily to some than others.

Confusion leads to misalignment and misinterpretation, which leads to delays in design and construction. This costs money, both for the clients and for their team.

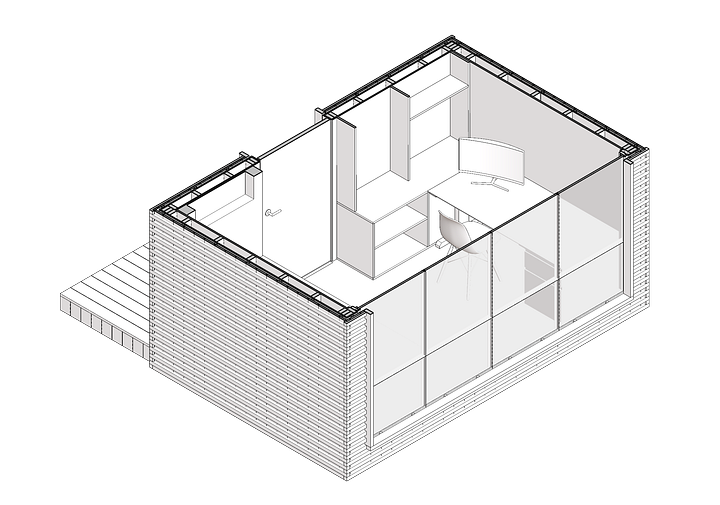

It makes designing easier. For us, there’s two main benefits to 3D modeling everything. First, just like for the client, it makes our decisions clearer. That ceiling height we drew might feel a little high. That tolerance we accounted for in the millwork might be able to get a little tighter. Second, it lets us get ideas out quickly and see multiples side by side. It’s the first step we take from going from sketch to visualization.

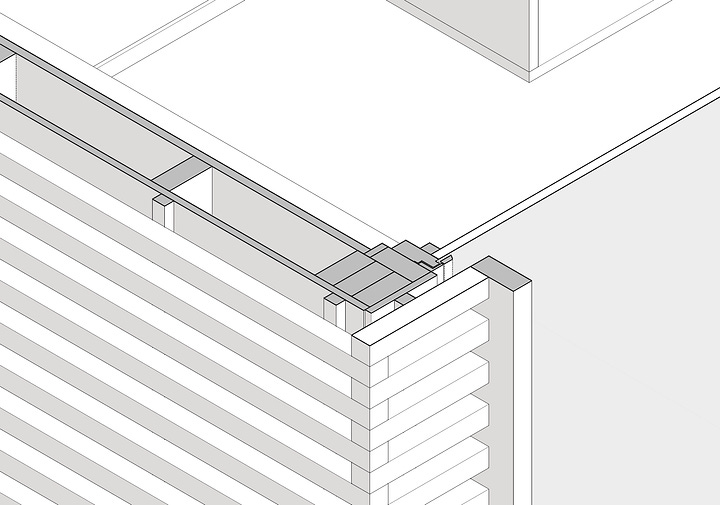

It makes constructing easier. On complex builds, we can model down to the studs, making estimating and material takeoffs much more accurate, which in turn reduces cost and time. Estimating cost of construction is one of the more difficult and time consuming parts of

It reduces confusion on the job site. During construction, we hang large scale prints of photo-realistic renderings for the contractors to see. This is massively helpful for them, as it gives them a clear vision of the exact finished product we’re aiming for.

At some point, it just seemed ridiculous to me that these things weren’t natively integrated into our process. At the end of the day, we have a housing crisis and we need to build better, faster and more affordably. This seems like an easy way to move in that direction, and we’re going to take it.

If you’re interested in working with us on a custom design project or would like to discuss purchasing our plans or a prefabricated unit, please email hello@offsite.camp or respond directly to this email!

-Brian

A note on AI. We get asked a lot…”Can you just generate something quickly in AI?” The answer is no…While we are constantly experimenting with its capabilities and there are some promising softwares being developed, its still unusable for any real type of visualization or design modeling. Unless you’re OK with completely random designs and materials being spit out, then you should go for it! We find that our large curated database of inspiration images and details that we’ve compiled over the years from amazing projects and designers serves as a much better reference source, and that we still need to model and specify materials on our own. Plus we like designing things…